What effect does temperature have on choosing the right coating?

As specialists in preserving and upgrading metal surfaces, we know how important it is to apply the right type of coating. In fact, we have been doing this since 1967 for a variety of industries, for different applications and temperatures. And the latter, that’s what we are going to talk about in detail in this article.

We understand that each product is unique and that each industry has certain requirements for the use of a plastic coating. That’s why, together with our customer, we always take a critical look at the application of the product.

Which coating on which product?

Which coating is used on a product depends on several criteria. The application of the product and the temperature in which the product is used are the two most important factors. For example, will the product be in contact with water or with chemicals? Is the temperature extremely high or somewhat lower, for short or longer period? In addition, the purpose of the coating and the customer’s requirements are taken into account. For example, should the coating be corrosion-resistant or have anti-adhesive properties? Based on these factors, we will examine whether the temperature at which the product will be used is feasible with a certain coating.

Maximum temperature

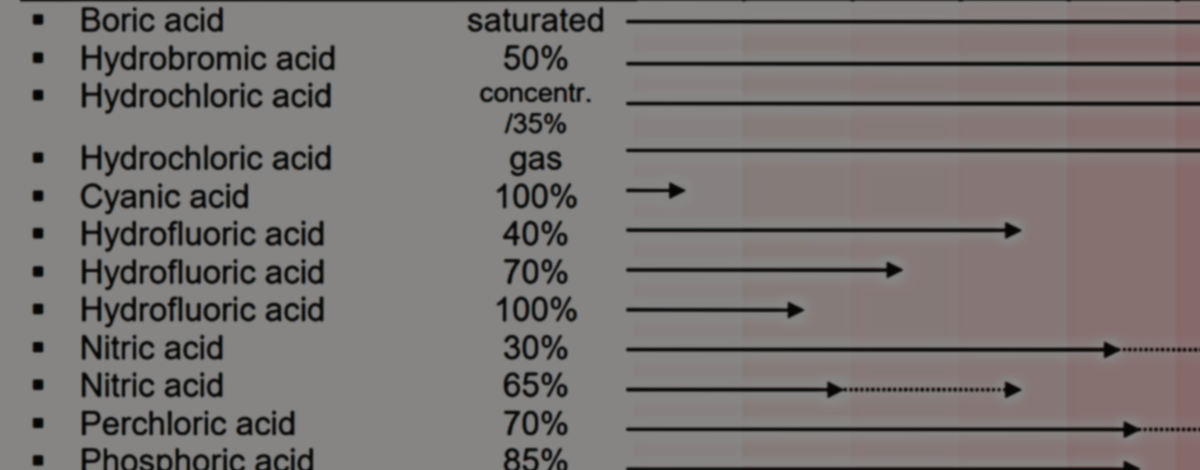

Each coating has a maximum operating temperature for each medium with which it comes into contact. It’s possible that a coating with a certain medium works well at a low temperature, but is less or not suitable at high temperatures. For example, a Rilsan coating is fine for a 50% sodium hydroxide solution at 20°C, but not suitable for the same medium from 60°C. So the temperature of the medium plays a very big role in choosing the right coating.

The maximum operating temperature that Kersten coating technology offers with some of the available coatings is 260°C. The suitability of the coating also depends on the medium used and the purpose of the coating.

When is this especially important?

It is especially important to apply the right coating when using high temperatures. At low temperatures, most coatings are suitable, but factors such as the medium for which the product will be used are still considered. The packaging, food and pharmaceutical industries are industries where high temperatures are commonly used.

Temperature too high

Has the temperature become too high? Then the coating may be affected or damaged. In that case, the product will have to be recoated. By obtaining all the necessary information about the product in the preliminary phase, we can provide the customer with clear information about the suitability of the coating in the application and what the maximum temperature limits are, for example. As a result, the customer knows how the applied coating can be used safely, so that exceeding the maximum temperature rarely happens again.

The right coating for your product

Before a product is coated, we always have a chat. As you can see, we want to know all the specifications and the application before we can determine which coating is suitable. Do you already have a particular coating in mind? Together we will look at the feasibility and provide you with appropriate advice.

Do you have a project that requires craftsmanship and expertise, small or large? Feel free to contact us, we are happy to think along with you.

Back to the overview