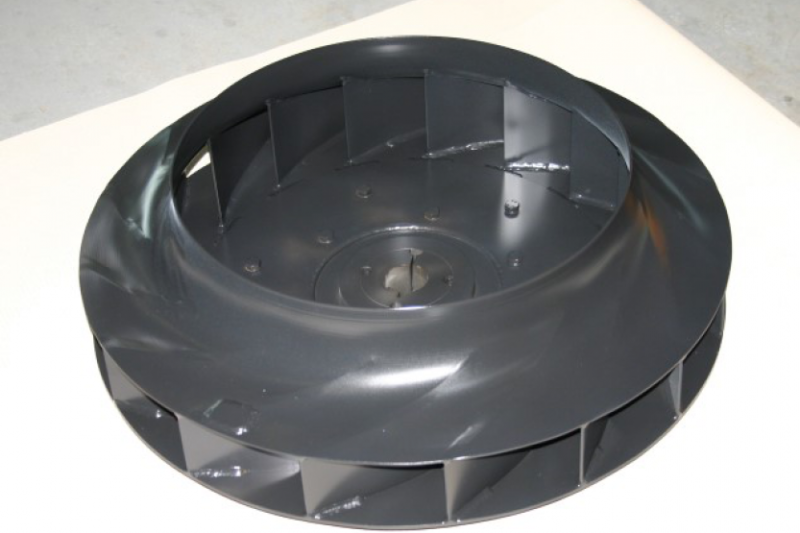

Coatings mechanical engineering

The industry of mechanical engineering is a very diverse market. We coat machine components that are used in the production processes of food and which are therefore subject to various approvals. Agricultural machinery and components for the automotive industry also have to comply with various requirements. We offer several solutions for all these applications.

A few examples of the coatings we use are Rilsan® for protection against corrosion, Halar® as corrosion protection against highly aggressive media and Xylan® as a non-stick coating on e.g. sliding plates or sealing plates. These coatings are applied by a fluidized bed process, electrostatic powder coating and / or as a wet lacquer.

Related coatings

Solutions

Frequently asked questions

- Xylan®

- ETFE

- Halar®

These coatings are mainly used in the pharmaceutical and food industry. The final products of these companies are often exported outside the Netherlands, which means that the coatings used in the production process must comply with European standards.

The following coatings are available in a vapor-tight version:

- Halar®, ECTFE

- ETFE

- PFA Ruby Red

Coatings used in contact with food must meet strict requirements. These coatings are not allowed to release any harmful substances into the food. In Europe the coatings must meet European standards, while in America the coatings must have an FDA approval.

Kersten applies plastic coatings using thermal processes. The main coatings are:

- Rilsan®, biobased Nylon 11

- Resicoat®, epoxy

- Halar®, Fluoropolymer ECTFE

- Xylan®, Fluoropolymers, PTFE, FEP and PFA

- Other Fluoropolymers including ETFE

- Abcite®, thermoplastic

The plastic coatings are applied in our production in Brummen (NL) or in Kahla (D) using thermal processes. The parts to be coated are heated in indirectly fired ovens, after which the coatings are applied. The coating techniques we mainly apply are:

- Fluidized bed coating

- Electrostatic powder spraying

- Rotomoulding