Waste-, sewer- and cooling water treatment

Plastic coatings are used for waste-, sewer- and cooling water treatment and transportation. They provide long-term protection of metal against corrosion. The coating selection depends on the temperature and aggressiveness of the water.

Typicaly withIn this sector, pipeline elements and components that are in contact with aggressive gases, are coated. We often apply Rilsan® by using a fluidized bed process. This coating is suitable for both fresh and salt water. Metal components coated with Rilsan® are a cheaper alternative to stainless steel.

Related coatings

Solutions

Frequently asked questions

Fluidized bed coating has the following advantages:

- Specific parts with difficult-to-access surfaces can be coated easily and in a controlled manner.

- In one operation a layer thickness of 400μm is applied, both internally and externally.

- It is an efficient coating method with very low powder loss.

PPG / Whitford's Xylan® coatings are particularly suitable for these applications. However Xylan® is a large family of coatings with different subgroups and specifications. If you wish to receive further information about these subgroups, please contact us !

Chemical resistance is the degree to which a coating is resistant to a specific chemical medium. The concentration of chemical substances and the temperature of the medium have a major influence on the level of resistance. We can advise you about the possibilities of our coatings.

The answer to this question is complex and cannot be answered shortly. Each coating has a certain chemical resistance. Per situation we can determine which coating suits best as application. We are happy to advise you on this.

The UV resistance of a coating is the degree to which it is resistant to, for example, sunlight.

If a coating is used outside it has to be resistant to sunlight. There are situations where UV is used for disinfection of for instance liquids. If coatings are used they have to be resistant to UV in this application.

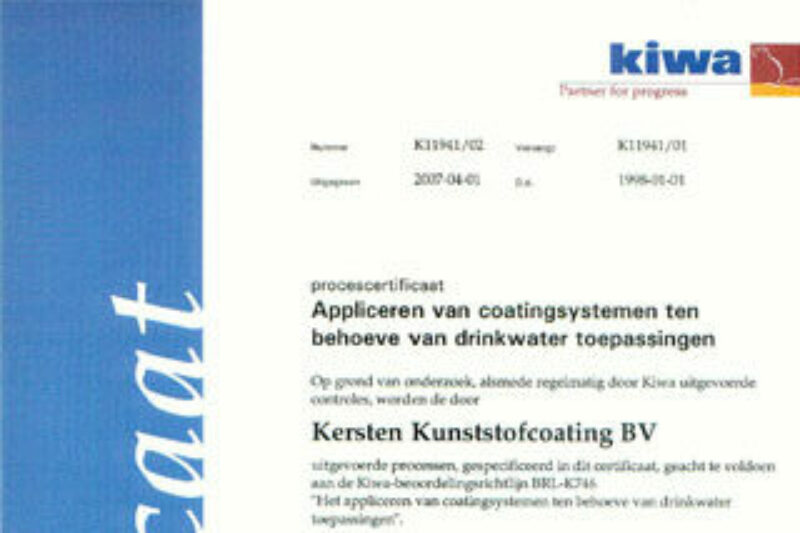

Kersten has the following Kiwa Evaluation Guidelines, which are necessary for the processing of coatings in the drinking water sector.

- BRL-K746, (application of coating systems for drinking water applications)

- BRL-K759, (coating systems for drinking water applications)

- BRL-K758, (construction guidelines for metal products to be coated)

The official Kiwa Evaluation Guidelines form a quality system which guarantees the good quality of the coating and the way it will be applied. In addition Kersten is audited several times a year by Kiwa to guarantee the quality.

The coatings that comply with the strict rules of Kiwa are approved types of the following coatings:

- Rilsan®

- Resicoat®