Resicoat®

Certified by Kiwa, DVGW/KTW and WICS – as well as being wear-resistant

Resicoat® is a plastic coating based on an epoxy resin. This high-quality coating is chemically resistant and hard-wearing. It does not contain any solvents. Resicoat® is certified by Kiwa, DVGW and WICS to use with drinking water. Its key application is the coating of cast iron items such as pipeline components, connecting pieces and valves.

Colours and layer thicknesses

We apply Resicoat® by fluidized bed coating and electrostatic powder coating. The commonest colour is blue, but other colours are available on request. The average layer thickness that we apply is approximately 400 μm.

Solutions

Sectors

Frequently asked questions

Fluidized bed coating is a process in which preheated parts are immersed in a powder bath. This powder is kept in vortex by blowing air through the porous bottom of the bath. This causes the powder to behave as being a liquid. When the blasted and heated part is subsequently immersed in the whirlpool bath, the powder particles melt down as a solid layer.

Both small and large parts can be provided with a coating using a fluidized bed. Especially pipe sections, couplings and fittings are provided with coatings using this technique. Kersten has options to cover parts with a length of 6 meters and a diameter of approximately 1.5 meters within this process

Fluidized bed coating has the following advantages:

- Specific parts with difficult-to-access surfaces can be coated easily and in a controlled manner.

- In one operation a layer thickness of 400μm is applied, both internally and externally.

- It is an efficient coating method with very low powder loss.

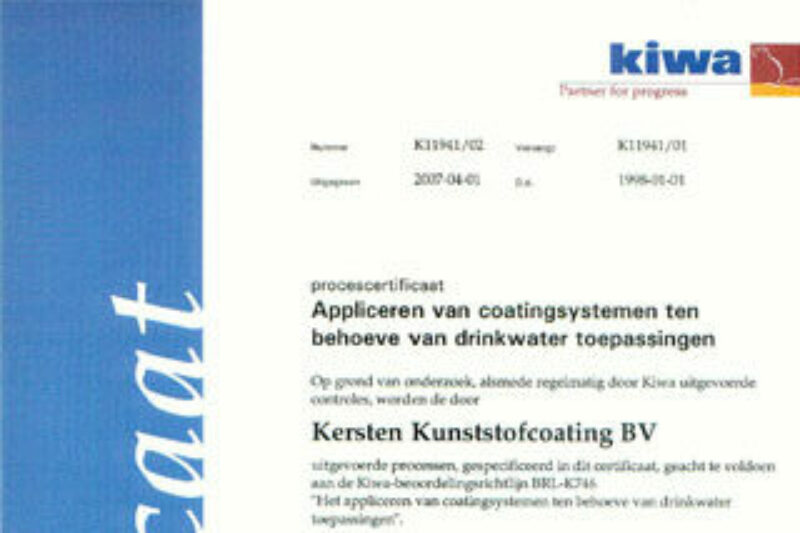

Parts used for production or transport of drinking water must be Kiwa certified. This is applicable for all coatings that are in contact with drinking water during the production process.

The official Kiwa Evaluation Guidelines form a quality system which guarantees the good quality of the coating and the way it will be applied. In addition Kersten is audited several times a year by Kiwa to guarantee the quality.

Kersten has the following Kiwa Evaluation Guidelines, which are necessary for the processing of coatings in the drinking water sector.

- BRL-K746, (application of coating systems for drinking water applications)

- BRL-K759, (coating systems for drinking water applications)

- BRL-K758, (construction guidelines for metal products to be coated)