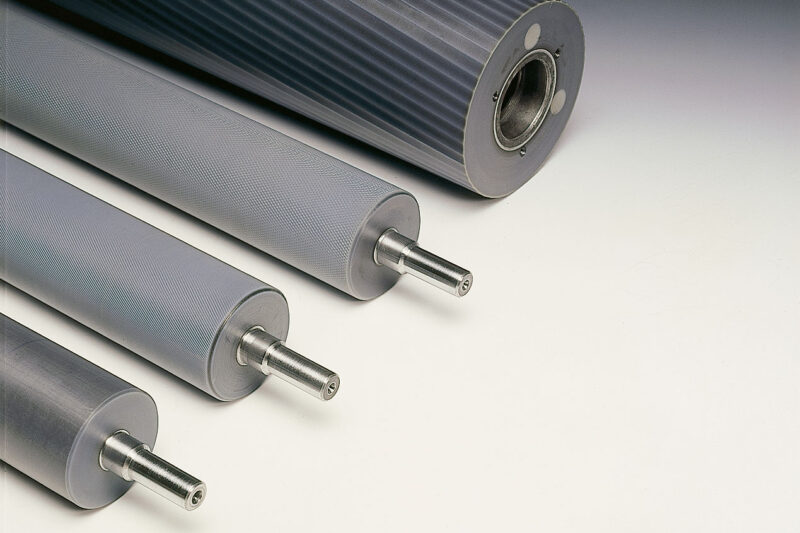

Flexible coatings

Flexible plastic coatings or thermoplastics do not harden after they have been applied. When these coatings are heated up towards their melting points, they soften again. Even after many years. Throughout the operational lifespan of the coating they remain flexible.

We use fluidized bed or electrostatic powder techniques to apply elastic coatings to metal surfaces that deform or have to remain flexible, such as springs. We apply both thin and thick layers of these coatings to components that are subject to increased wear and tear. This is because thermoplastics are more resistant to e.g. cavitation than thermosetting plastics.

Related coatings

Sectors

Frequently asked questions

An elastic coating is a plastic coating that does not harden after being applied and is called a thermoplastic. These plastics become soft again when they are heated to their melting point, even after many years.

The main elastic plastic coatings applied by Kersten are:

- Rilsan®

- Halar®

- ETFE

- Fluoropolymers

- Abcite®.

These elastic coatings can be applied to metal surfaces that deform, such as springs. These coatings are also applied in case high wear is expected. As well, a thermoplastic coating is more resistant to cavitation than a thermoset.

These coatings are applied by fluidized bed coating or electrostatic powder spraying.